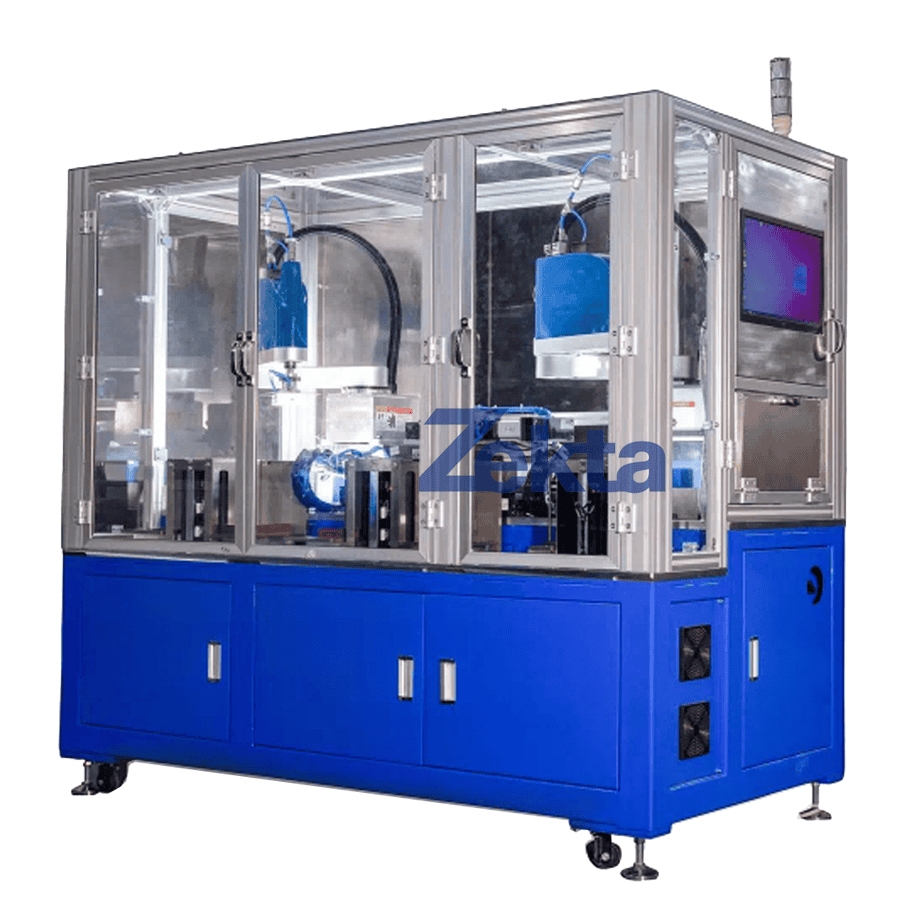

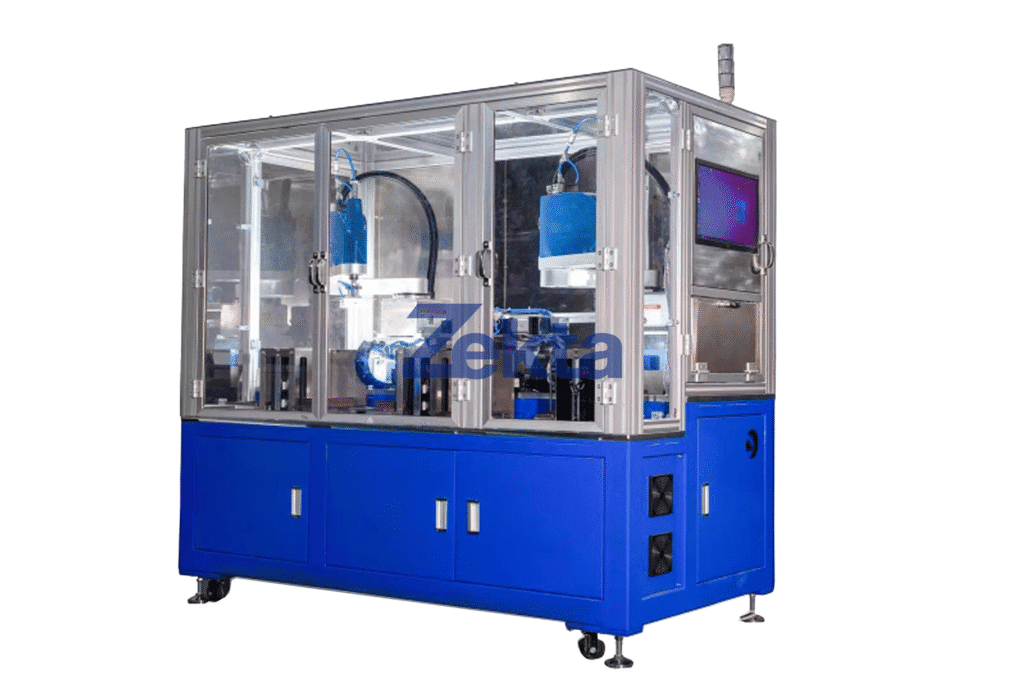

Custom Non-Standard Automation Equipment

description

Custom Non-Standard Automation Equipment

Our custom non-standard automation systems are engineered to meet the unique production needs of clients across a wide range of industries. Whether you’re in electronics, automotive, medical devices, new energy, precision machinery, packaging, or materials processing, we deliver tailor-made automation solutions that enhance productivity, precision, and consistency.

Key Features:

-

Fully Customized Design: Solutions are developed based on customer requirements, product specifications, and process flows—ensuring seamless integration with existing systems.

-

Wide Application Scope: Covers assembly, inspection, labeling, packaging, material handling, bonding, welding, coating, testing, and more.

-

Flexible Configuration: Supports single-station, modular, or fully automated production lines, with options for robotic arms, vision systems, and MES integration.

-

High Efficiency & Reliability: Designed for 24/7 industrial operation with stable performance, fast cycle times, and low downtime.

-

Smart Control Systems: Equipped with PLC, HMI, SCADA, and IoT compatibility for real-time monitoring, remote diagnostics, and intelligent upgrades.

-

Cross-Industry Compatibility: Successfully deployed in semiconductor, consumer electronics, optics, automotive parts, medical manufacturing, lithium battery, and photovoltaic industries.

Advantages:

-

Short lead times and rapid prototyping

-

Expert mechanical and electrical design teams

-

CE-compliant and ISO-certified quality control

-

Long-term support, upgrades, and maintenance services

Applications Include:

-

Precision dispensing machines

-

Custom assembly lines

-

Vision inspection stations

-

Robotic pick-and-place units

-

Automated packaging solutions

-

Ultrasonic welding systems

-

Palletizing and sorting stations

-

Laser marking and engraving platforms