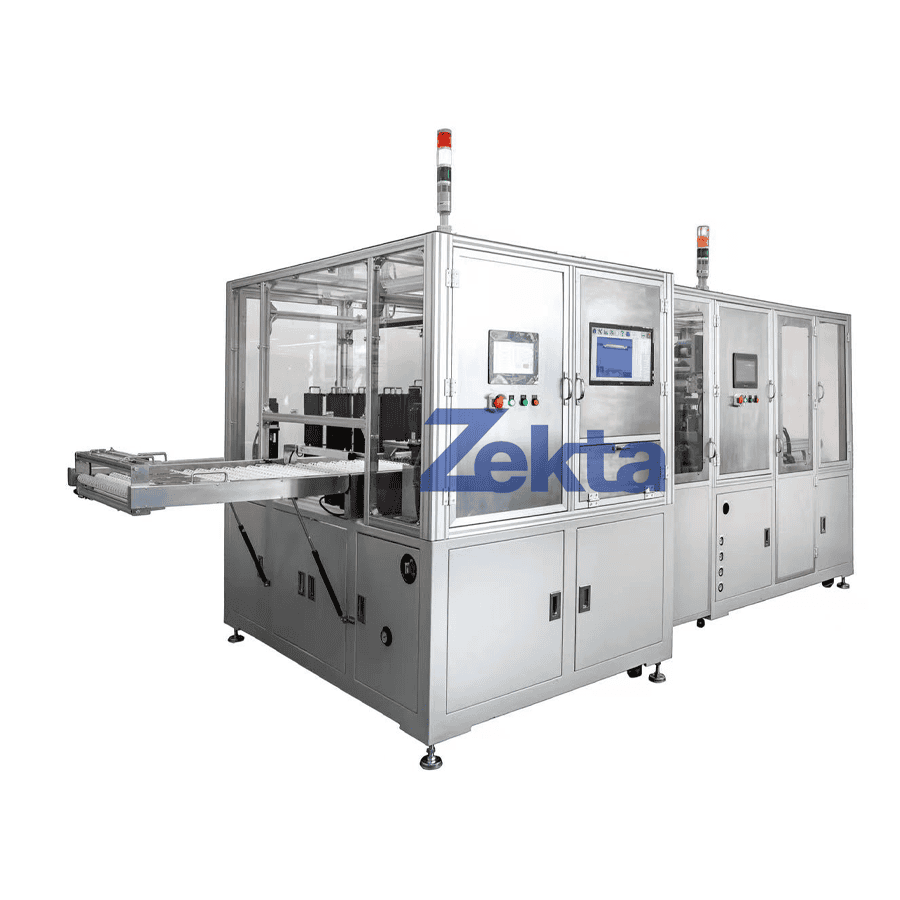

Ceramic Substrate Laminating Machine

description

Our film laminating machine is engineered for precision and reliability, offering superior performance for high-yield applications. Key features include:

-

Direct Lamination without Pre-Tacking

The substrate and dry film are simultaneously fed directly beneath the pressure rollers for lamination, eliminating the need for pre-tacking. This reduces the risk of air bubbles and wrinkles during the initial stage. -

Multi-Roller Pressure Design

Equipped with a multi-roller system, the machine ensures stable lamination and compensates for external factors that may cause substrate deviation, minimizing film misalignment and wrinkling. -

Dual-Side Lamination Rollers

Front and rear pairs of pressure rollers enhance adhesion between the dry film and the substrate, significantly improving lamination yield and bonding strength.

Specifications

Rigid/Flexible Board Laminating Machine Series

The following specifications are for reference only and can be customized based on actual requirements.

| No. | Item | Specifications |

| 1 | Equipment Dimensions | L2600×W1600×H2000mm (excluding alarm light height) |

| 2 | Equipment Weight | Approx. 1500kg |

| 3 | Substrate Dimensions | Width: 110mm(min.) – 150mm(max.) Length: 110mm(min.) – 300mm(max.) Thickness: 0.1-3.2mm (with copper); Warpage: ≤1mm |

| 4 | Dry Film Specifications | Width: 110(min.)-300(max.)mm Roll core diameter: 3 inches; Dry film outer diameter: 250mm(max.) |

| 5 | Heating Temperature | Room temperature – 120℃ (±5℃) |

| 6 | Pressure Range | 0.3-0.6kg/cm² |

| 7 | Copper Exposure Accuracy | ±1mm |

| 8 | Working Surface Height | 1050±50mm |

| 9 | Conveying Speed | Adjustable 1-5m/min |

| 10 | Laminating Speed | Adjustable 1-3m/min |

| 11 | Power Supply | Single-phase 220V, 50Hz, 12KW |

| 12 | Air Source | 4-6kg/cm², 200L/min |