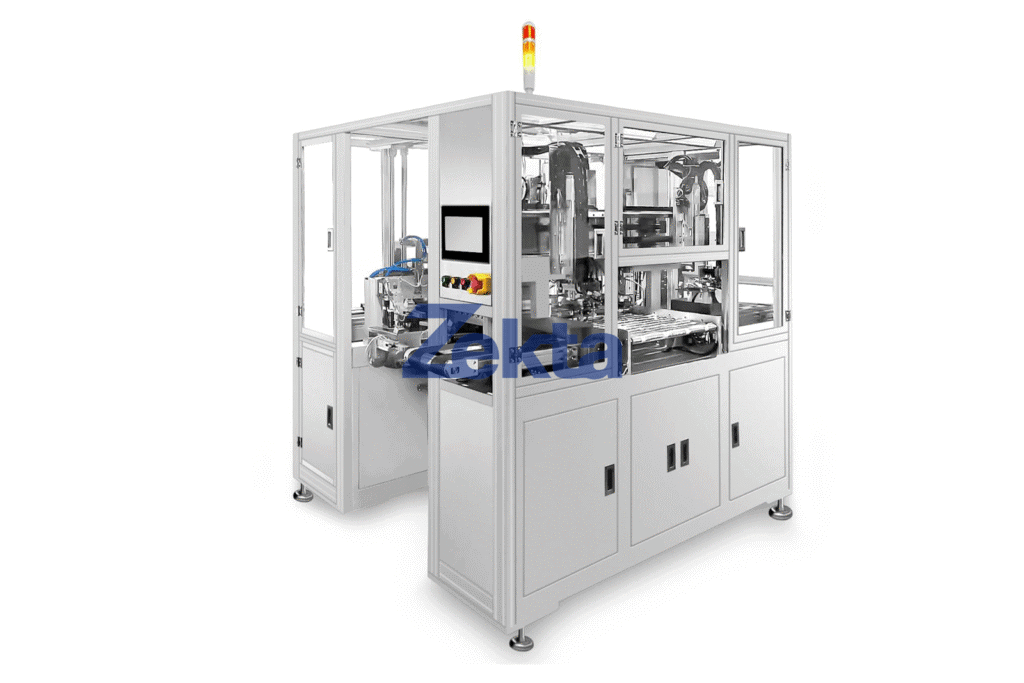

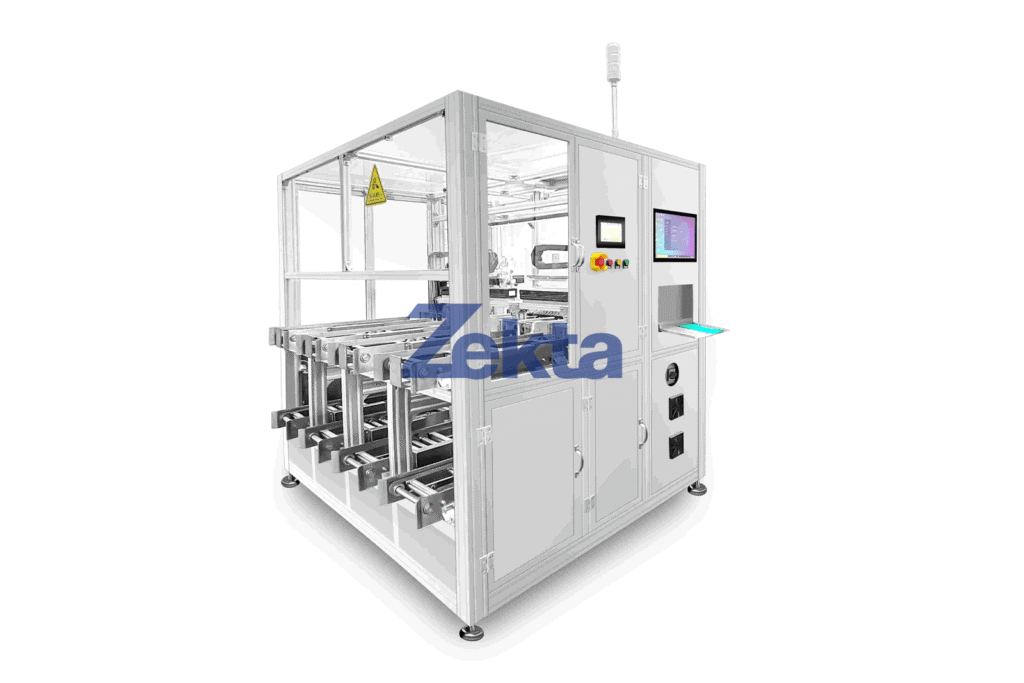

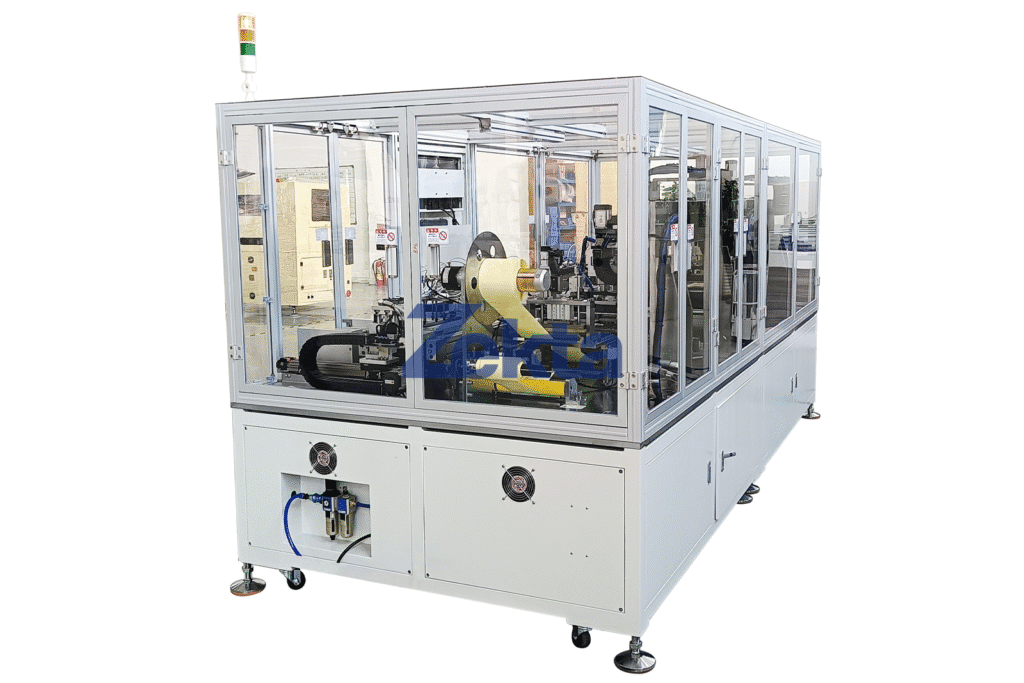

Smart Non-Standard Automation Equipment Manufacturer

Leading Expert in Custom Automation Solutions

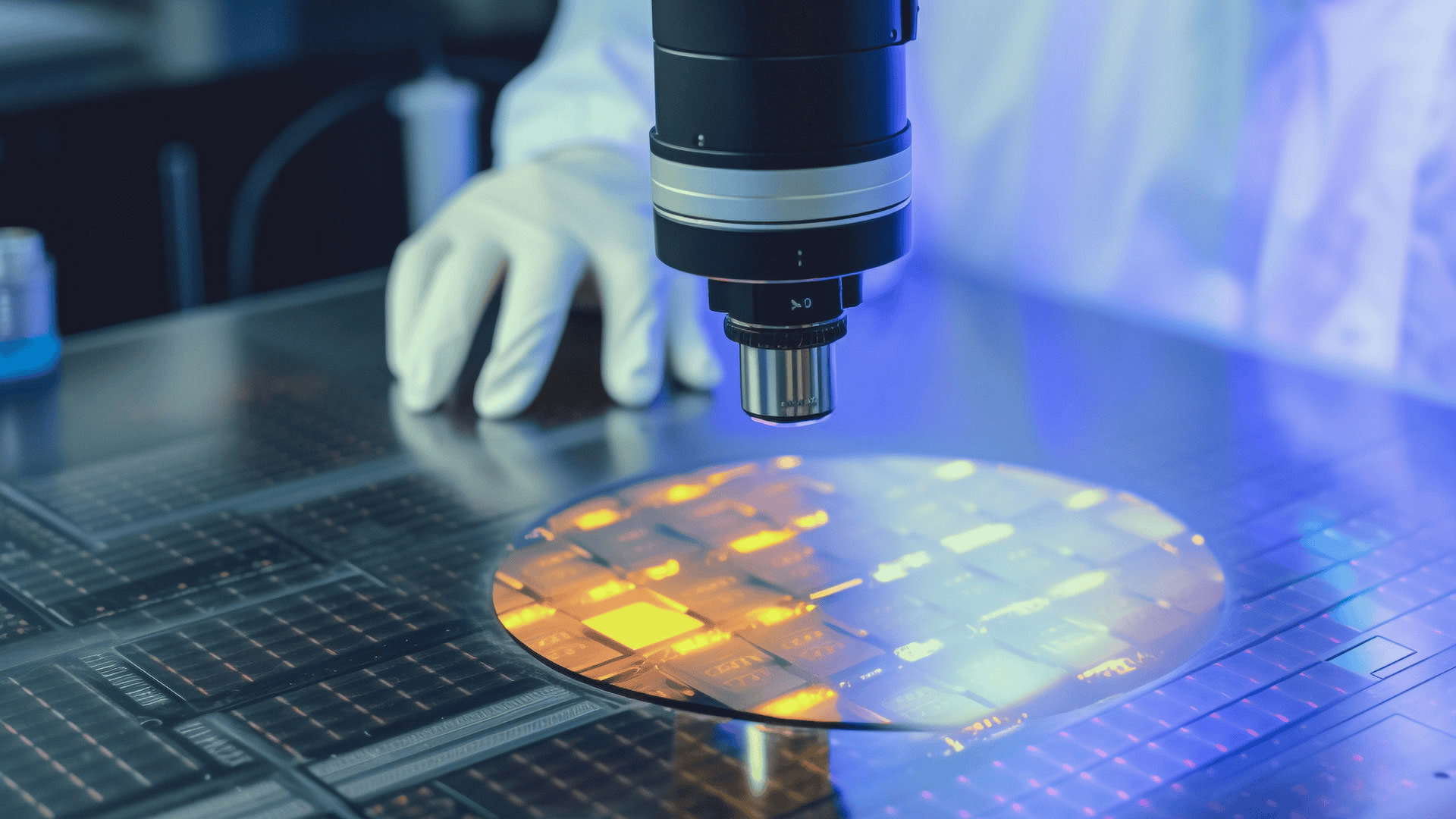

Zekta Automation is a leading provider of custom non-standard automation systems, specializing in robotic integration and smart factory solutions. With deep expertise in PCB, semiconductor, photovoltaic, and panel lamination processes, we deliver high-precision equipment including laminators, vacuum press systems, and tailored inline automation for complex manufacturing needs.

Zekta delivers automation solutions that easily adapt to diverse application scenarios

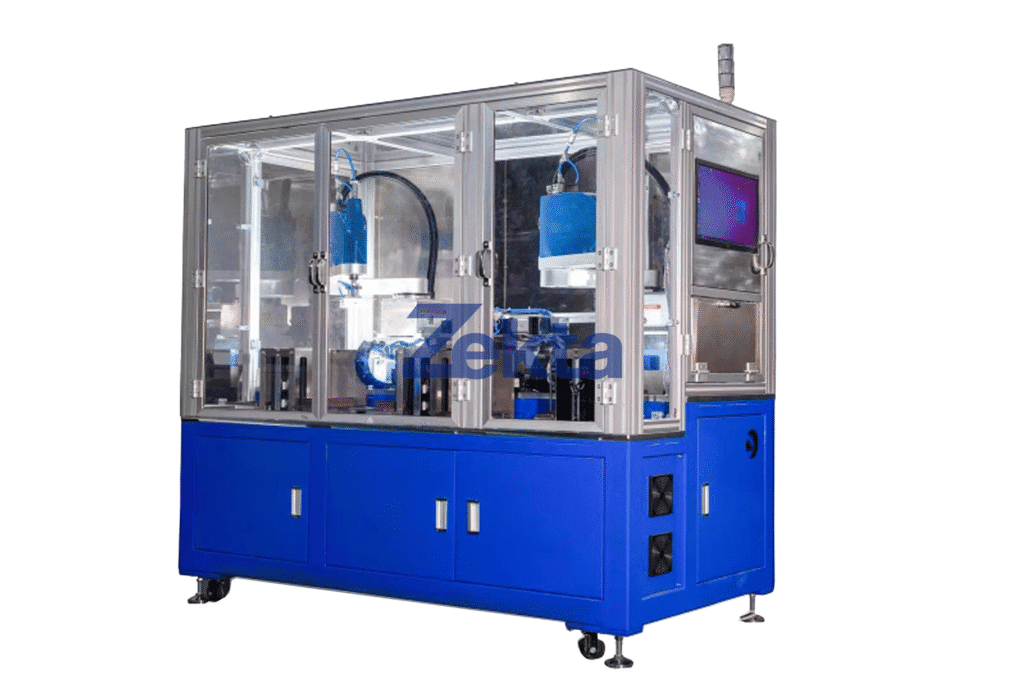

Film Laminating Machine

learn more

Film Peeling Machine

learn more

Unwinding and Rewinding Machine

learn more

Vacuum Film Laminator

learn more

Glass Laminating Machine

learn more

Custom Automation

learn moreWhy Zekta?

Advanced R&D

Precision Engineering

Turnkey Solutions

Global Compliance

Zekta Automation News & Updates

Robotic System Integration and Automation: A New Revolution in Manufacturing and Services

PCB Industry Continues to Thrive, Driving Intelligent Manufacturing Upgrades

Custom Automation Equipment: The Key to the Future of Advanced Manufacturing

Innovative Technology Driving a New Era: Vacuum Lamination Machines Reshape the Future of Manufacturing

Let’s Talk About Your Project

What types of automation equipment do you specialize in?

We focus on non-standard automation equipment, including laminating machines, vacuum lamination systems, film peeling machines, and related inline automation solutions for industries like semiconductors, PCB, glass substrates, and advanced ceramics.

Do you provide customized automation solutions?

Yes. All our equipment can be tailored to meet your specific process, space, and performance requirements.

What industries do you mainly serve?

We serve clients in PCB, semiconductor, photovoltaic, ceramic substrate, glass substrate, and display panel industries.

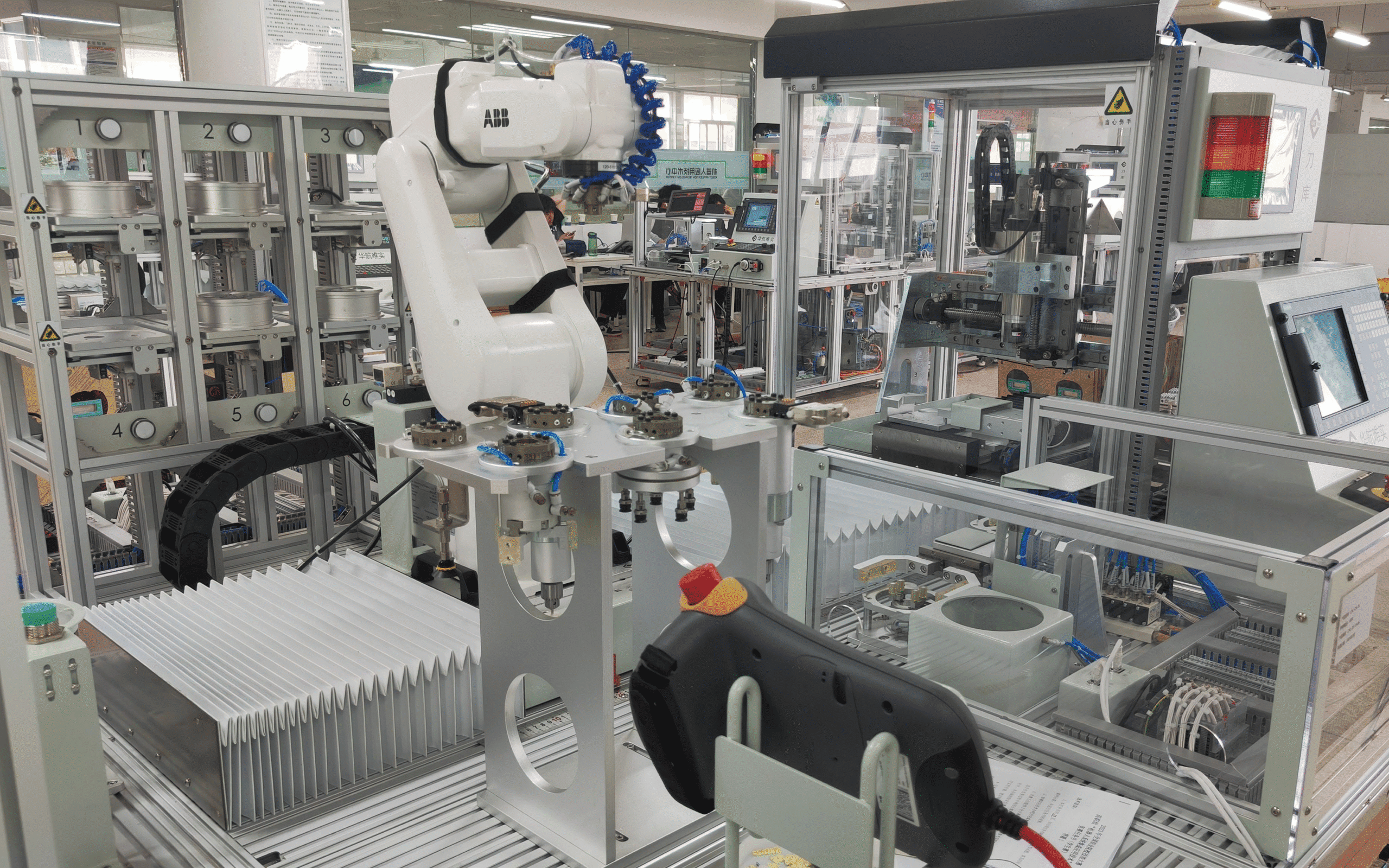

Can you integrate robots into your automation systems?

Absolutely. We offer full robotic integration and system-level automation to enhance production flexibility and efficiency.

What is the typical lead time for custom equipment?

Lead time varies by project complexity, but most systems are delivered within 8–14 weeks after final specification confirmation.

What is your payment terms?

Our payment term is 30% advance payment and 70% balance payment before shipment.

Are your machines compliant with international standards?

Yes. Our equipment is compliant with ISO9001, CE, and other global safety and quality standards.

Do you offer installation and training services?

Yes. We provide on-site installation, commissioning, and comprehensive operator training worldwide.

What kind of after-sales support do you provide?

We offer 24/7 remote technical support, on-site maintenance options, and spare parts supply for long-term reliability.

Can your systems be upgraded or expanded later?

Yes. Our modular design allows for future upgrades, retrofitting, and system expansions as your production needs evolve.

How can I request a quote or technical consultation?

You can contact us directly via our website contact form or email. Our team will respond within 24 hours with a tailored solution.

Can your equipment handle ultra-thin or fragile materials?

Yes. Our systems are engineered to handle delicate substrates, including ultra-thin glass (down to 0.1mm) and ceramic panels, with high precision and safety.

What makes your solutions different from other automation providers?

Our strength lies in high-level customization, patented technologies (e.g., dual-lane lamination and peeling), and deep integration of automation with smart factory systems.

Do you support turnkey automation projects?

Yes. We offer full turnkey project services—from design and engineering to fabrication, integration, and commissioning—ensuring a smooth and efficient deployment.