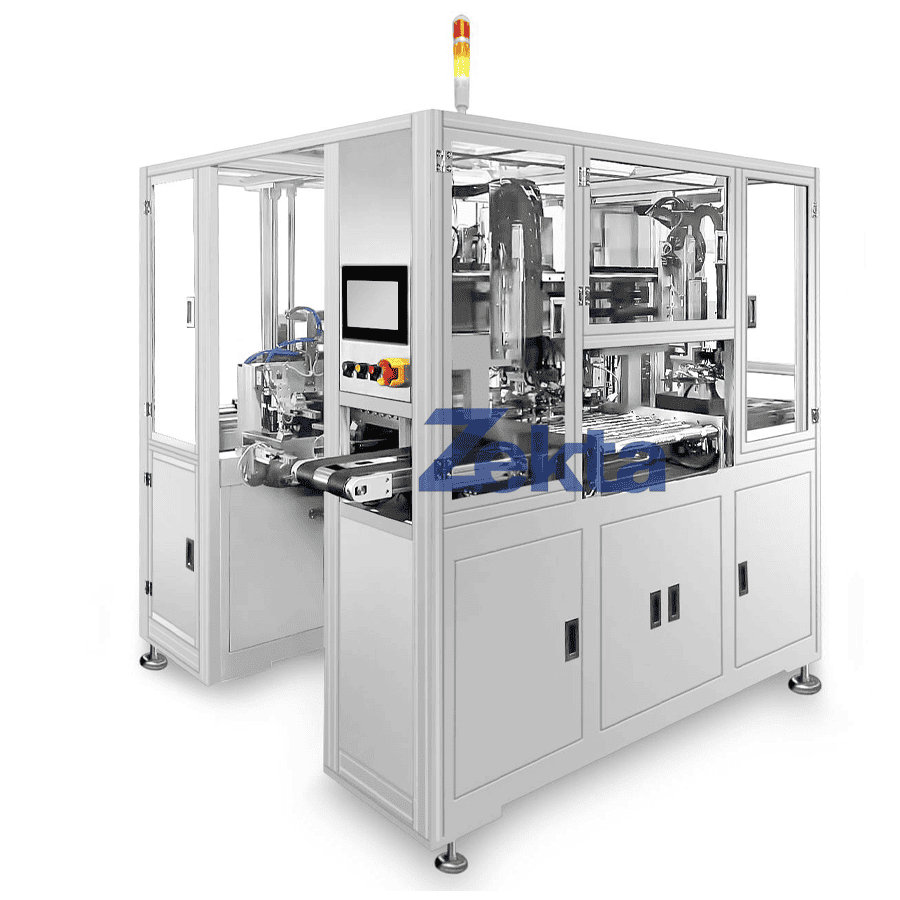

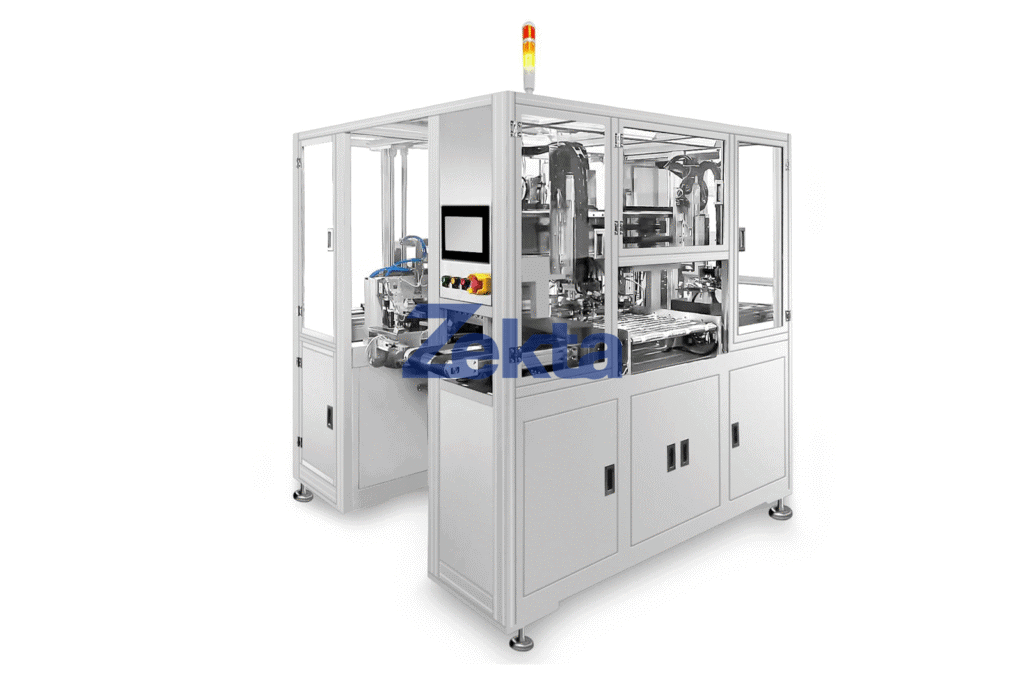

Ceramic Substrate Film Peeling Machine

description

This machine is designed for precision film peeling of dry film protective layers from ceramic substrates after the exposure process. It is also compatible with other small-sized substrates such as glass or specialty materials, making it versatile for various high-precision applications.

The system features fully automated loading, dual-substrate simultaneous peeling, and automatic alignment. After processing, four substrates are aligned into a single row and seamlessly conveyed to the developing line for the next stage. This streamlined process ensures high efficiency, consistent performance, and optimal integration into automated production lines.

Specifications

The following specifications are for reference only and can be customized based on actual requirements.

| No. | Item | Specifications |

| 1 | Equipment Dimensions | L2000×W2000×H2000mm (excluding alarm light height) |

| 2 | Equipment Weight | Approx. 1300kg |

| 3 | Substrate Dimensions | Width: 5 inches (138mm) Length: 7 inches (192mm) Thickness: 0.1-3.2mm (with copper); Warpage: ≤1mm |

| 4 | Edge Exposure | 1-5mm edge exposure (edge wrapping not suitable for this machine) |

| 5 | Buffer System | 2 buffer units, capacity for 30 substrates |

| 6 | Film Peeling Method | Ceramic plate tilt at right-angle position for film peeling |

| 7 | Efficiency | 12 substrates/min (excluding tape replacement and film collection time) |

| 8 | Working Surface Height | 1050±50mm |

| 9 | Conveying Speed | Adjustable 1-5m/min |

| 10 | Film Peeling Speed | Adjustable 1-3m/min |

| 11 | Power Supply | Single-phase 220V, 50Hz, 8KW |

| 12 | Air Source | 4-6kg/cm², 100L/min |