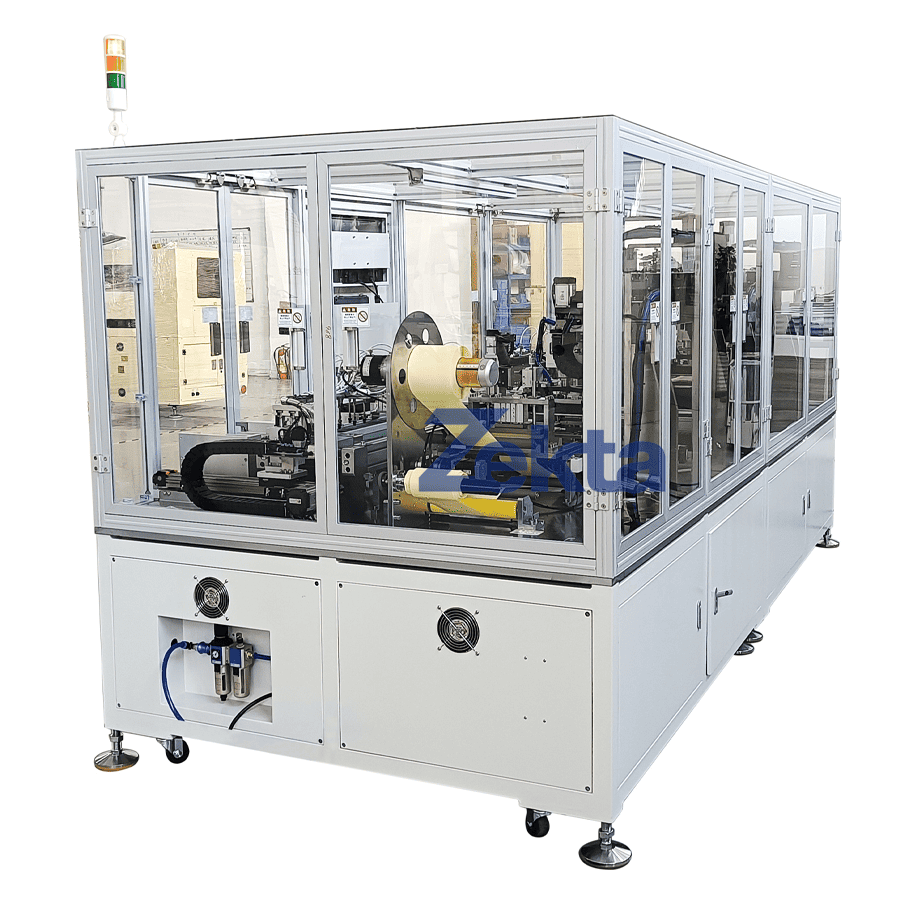

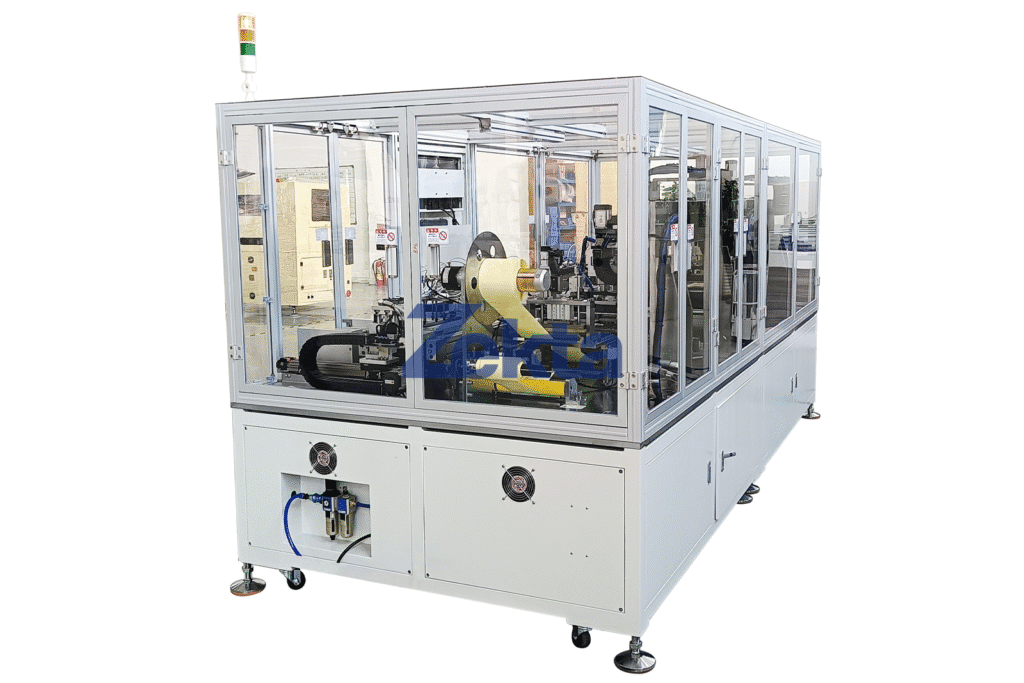

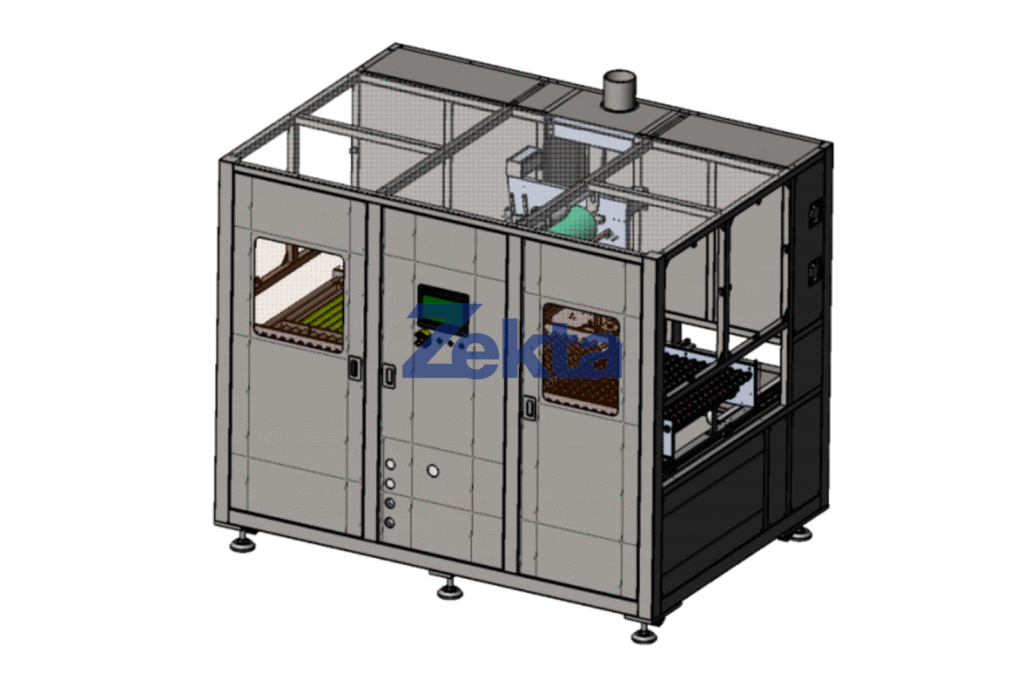

Composite Glass Lamination Machine

description

The Composite Glass Lamination Machine is engineered to deliver high-quality lamination for composite glass used in automotive, architectural, and electronic applications. Designed for precision and durability, this equipment ensures uniform pressure and temperature control throughout the lamination process, resulting in strong bonding and excellent optical clarity. Suitable for both small-scale and industrial production, the machine enhances efficiency with easy operation and reliable performance, meeting the rigorous demands of today’s glass manufacturing industry.

Specifications

The following specifications are for reference only and can be customized based on actual requirements.

| Parameter | Specification |

| Minimum Dimensions | 250*250*0.1mm |

| Maximum Dimensions | 550*650*2mm |

| Width Range | 250-630mm |

| Film Thickness | 15-50μm |

| Core Diameter | 75.6mm (diameter) |

| Maximum Outer Diameter | 200mm (when using removable dry film frame) |

| Film Absorption Method | Vacuum adsorption with automatic control of vacuum range based on substrate size |

| Lamination Roller Silicone Hardness | Standard 70° Shore, other hardness available upon request |

| Roller Outer Diameter | ø50mm |

| Metal Core Diameter | ø47mm (standard rubber coating thickness T=1.5mm, customizable) |

| Internal Heating Element | Fully enclosed IR heating tube |

| Roller Heating Rate | 20min from room temperature to 120℃ |

| Maximum Roller Temperature | 150℃ |

| Temperature Uniformity Control | ±3℃ (no load), ±5℃ (continuous production) |

| Lamination Pressure | 3.0-5.0kgf/cm² |

| Pressure Uniformity | When set to 2.5kg/cm², maximum and minimum indentation width variation ≤±1mm |

| Copper Exposure Accuracy | ±1.0mm (at production speed ≤3.5m/min) |

| Film Breakage Prevention | High-speed rotating disc blade for film cutting |

| Blade Type & Specifications | Disc blade ø64*1.0mm, service life >150,000 cycles |

| Ion Blower | Included |

| Film Lamination Process | Manual placement on positioning device, silicone roller transports into lamination roller |

| Cutting Process | After lamination, cutting blade moves horizontally to sever protective film |